Highly Conductive Binder-Free Inks For Printed Electronics

Highly Conductive Binder-Free Inks For Printed Electronics

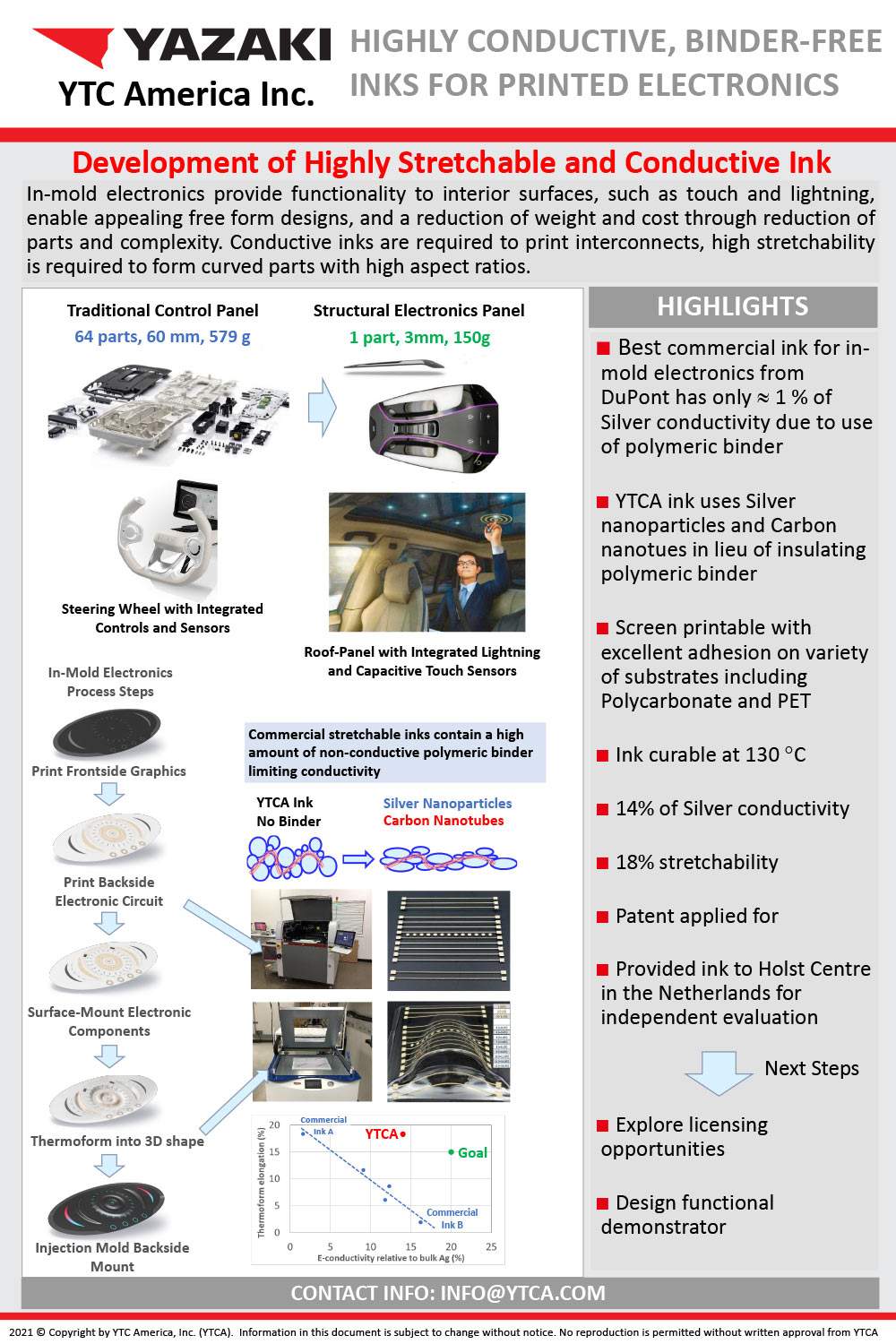

Development of Highly Stretchable and Conductive Ink

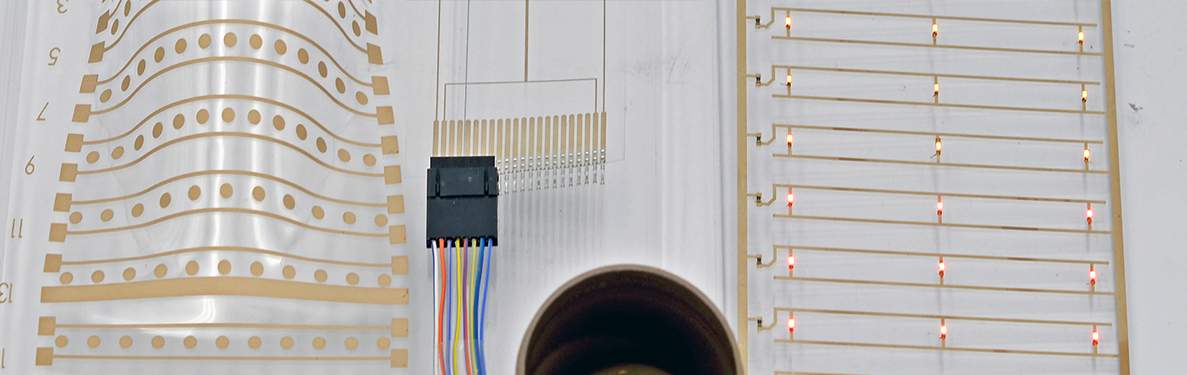

In-mold electronics provide functionality to interior surfaces, such as touch and lighting, enable appealing free form designs, and a reduction of weight and cost through reduction of parts and complexity. Conductive inks are required to print interconnects, high stretchability is required to form curved parts with high aspect ratios.

Highlights

- Best commercial ink for in-mold electronics from DuPont has only ≈ 1 % of Silver conductivity due to use of polymeric binder

- YTCA ink uses Silver nanoparticles and Carbon nanotubes in lieu of insulating polymeric binder

- Screen printable with excellent adhesion on variety of substrates including Polycarbonate and PET

- Ink curable at 130 °C

- 14% of Silver conductivity

- 18% stretchability

- Patent applied for

Development of Highly Stretchable and Conductive Ink

In-mold electronics provide functionality to interior surfaces, such as touch and lighting, enable appealing free form designs, and a reduction of weight and cost through reduction of parts and complexity. Conductive inks are required to print interconnects, high stretchability is required to form curved parts with high aspect ratios.

Highlights

- Best commercial ink for in-mold electronics from DuPont has only ≈ 1 % of Silver conductivity due to use of polymeric binder

- YTCA ink uses Silver nanoparticles and Carbon nanotubes in lieu of insulating polymeric binder

- Screen printable with excellent adhesion on variety of substrates including Polycarbonate and PET

- Ink curable at 130 °C

- 14% of Silver conductivity

- 18% stretchability

- Patent applied for